Industry Specific Remote Controls

Remote Source serves as your trusted industrial remote control supplier, delivering rugged control solutions designed for demanding commercial and manufacturing environments. Our industrial remote controls handle everything from air conditioning systems to complex machinery, ensuring reliable operation in conditions that would destroy standard consumer remotes.

From precision air conditioning controls for server rooms to heavy-duty wireless systems for factory equipment, our products are built to withstand the heat, dust, vibration, and electromagnetic interference that define modern industrial settings.

Industry Specific Remote Controls

Remote Control Solutions for Every Sector

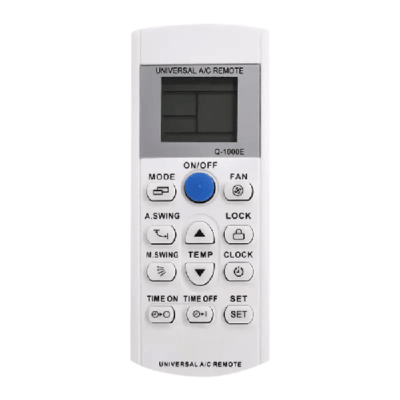

Air Conditioning System Controls

Climate control in commercial buildings, data centers, and manufacturing facilities requires precise temperature management that standard thermostats can’t provide. Our AC remote control series offers professional-grade functionality with clear digital displays, programmable schedules, and robust construction that handles continuous operation.

The RS-AC506, RS-AC505, and RS-AC502 models provide intuitive interfaces for complex HVAC systems, allowing facility managers to fine-tune temperature, humidity, and airflow from convenient locations. Large, backlit displays remain visible in low-light conditions, while sealed button construction prevents dust and moisture infiltration that typically causes control failures.

Heavy-Duty Wireless Solutions

Manufacturing environments demand industrial wireless remote control systems that maintain reliable communication despite electromagnetic interference from motors, welders, and power systems. Our wireless remotes operate on frequencies specifically chosen to avoid interference while providing the range needed for large facility operations. For extended-distance applications, explore our long range remote controls designed for mining, construction, and large industrial sites.

These systems control overhead cranes, conveyor belts, automated guided vehicles, and production line equipment from safe distances. Robust signal processing filters out noise while maintaining responsive control that operators depend on for precision movements and emergency stops.

Temperature Display Technology

Accurate temperature monitoring prevents equipment damage and ensures optimal operating conditions across various industrial processes. Our remotes feature high-contrast LCD displays that show precise temperature readings, even in bright sunlight or harsh lighting conditions common in industrial environments.

Multiple temperature sensors can be monitored from a single remote, allowing operators to track critical points throughout complex systems. Alarm functions alert operators when temperatures exceed safe limits, preventing costly equipment damage or production interruptions.

Rugged Construction Standards

Industrial remote control devices must survive daily abuse that would quickly destroy office equipment. Our remotes feature reinforced housings, sealed button assemblies, and shock-resistant internal components that maintain functionality despite drops, vibration, and exposure to industrial chemicals.

Extended temperature ranges ensure operation from freezing cold storage facilities to high-heat manufacturing environments. Water-resistant sealing protects against steam, condensation, and cleaning chemicals while maintaining the tactile button response that operators need for reliable control.

Multi-Zone Management Capabilities

Large facilities require control systems that can manage multiple zones, buildings, or production areas from centralized locations. Our industrial remote controls support complex addressing schemes that allow a single operator to control dozens of different systems without confusion or interference.

Color-coded displays and logical button layouts prevent operational errors that could disrupt production or compromise safety. Quick zone switching lets operators respond rapidly to changing conditions across multiple areas without navigating complex menu systems.

Electromagnetic Interference Resistance

Manufacturing environments contain numerous sources of electrical noise that can disrupt standard remote controls. Our industrial wireless remote control systems use advanced shielding and filtering techniques to maintain reliable operation near welding equipment, motor drives, and high-power electrical systems. For specialized RF communication needs, consider our OEM RF remote control and key fob solutions for custom industrial applications.

Frequency-hopping technology automatically avoids interference sources, while error-correction protocols ensure command integrity even in electrically noisy environments. Dual-band operation provides backup communication paths when primary frequencies experience interference.

Custom Programming Solutions

Different industries have unique operational requirements that standard programming can’t address. Our remotes support custom button mapping, specialized command sequences, and integration with existing control systems used throughout your facility. For comprehensive customization options, explore our full feature custom remote controls with advanced programming capabilities.

Macro programming combines multiple actions into single button presses, streamlining complex operations while reducing the chance of operator errors. Custom interfaces can match existing equipment controls, minimizing training time when upgrading or expanding systems.

Maintenance and Reliability

Industrial operations can’t tolerate equipment failures that disrupt production schedules or compromise safety systems. Our industrial remote control products undergo extensive testing for reliability, including temperature cycling, vibration testing, and electromagnetic compatibility verification.

Field-replaceable batteries and modular construction minimize downtime when service is required. Diagnostic functions help identify potential issues before they cause failures, while robust construction extends operational life far beyond consumer-grade alternatives.

Ready to upgrade your industrial control systems? Contact us today to discover how our industrial remote controls can improve safety, efficiency, and reliability across your operations while withstanding the demanding conditions that define modern manufacturing environments.